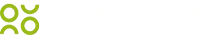

Round-the-clock machine tending starting from €2,080 / month

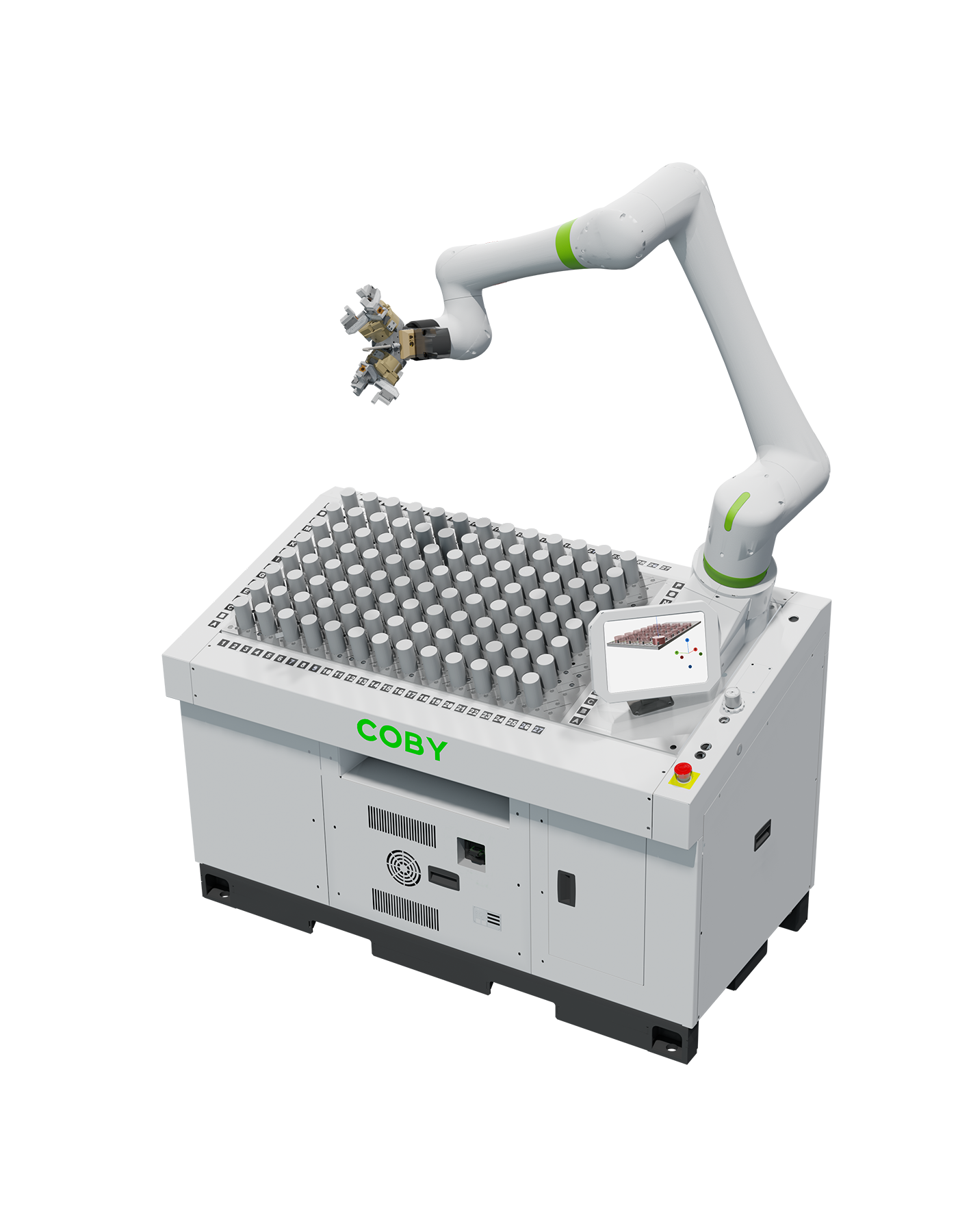

A collaborative robot system, compact and easy to use. Just what you want from a DIY solution.

Everything you need in one package. No technical expertise required. Optimize your CNC machine with the push of a button.

Ideal for small and medium batches

We like to keep it simple. From unboxing and installation to setting up your CNC automation. Quick. Compact. Lightweight. Easy to use. Everything you’d want from a DIY solution.

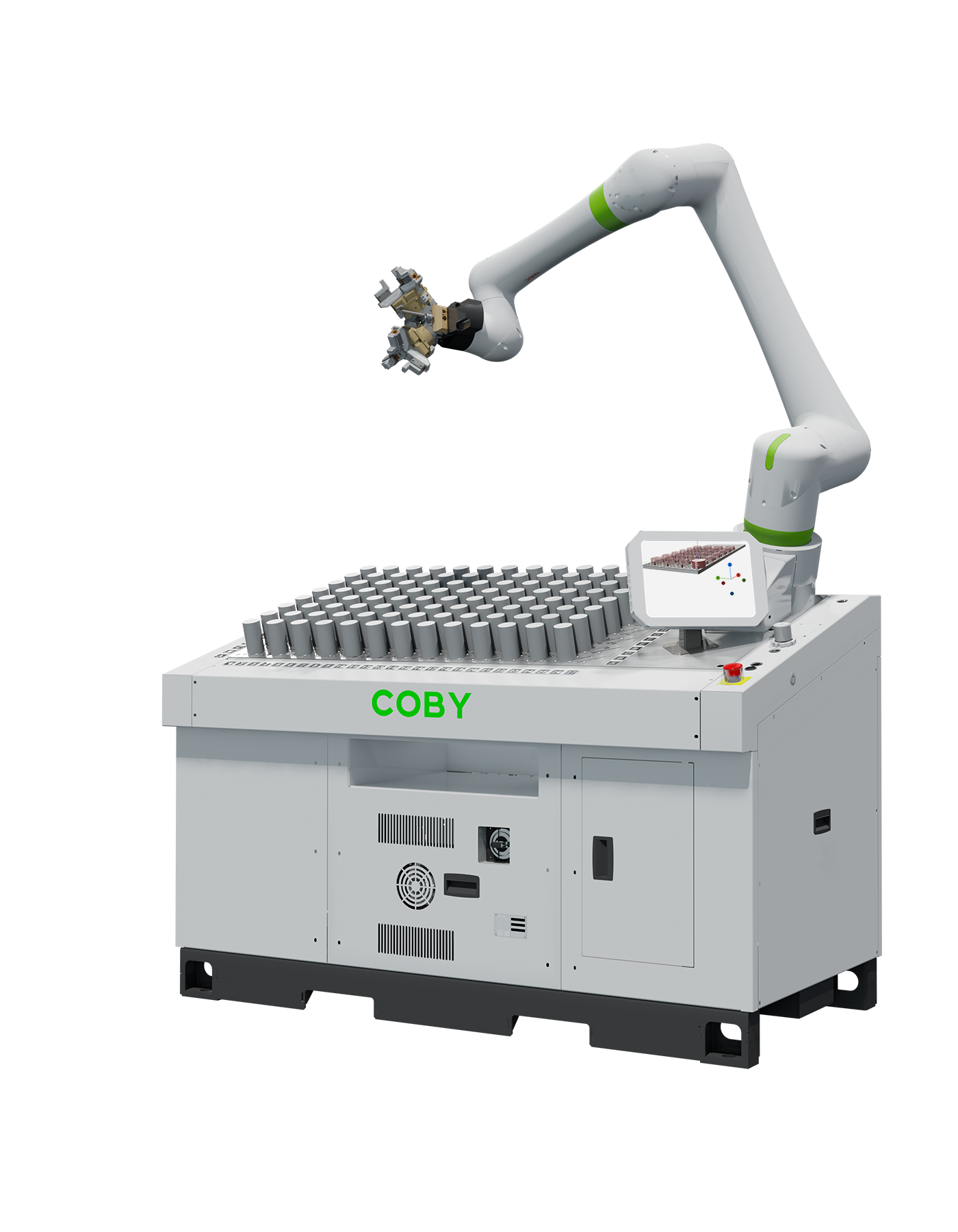

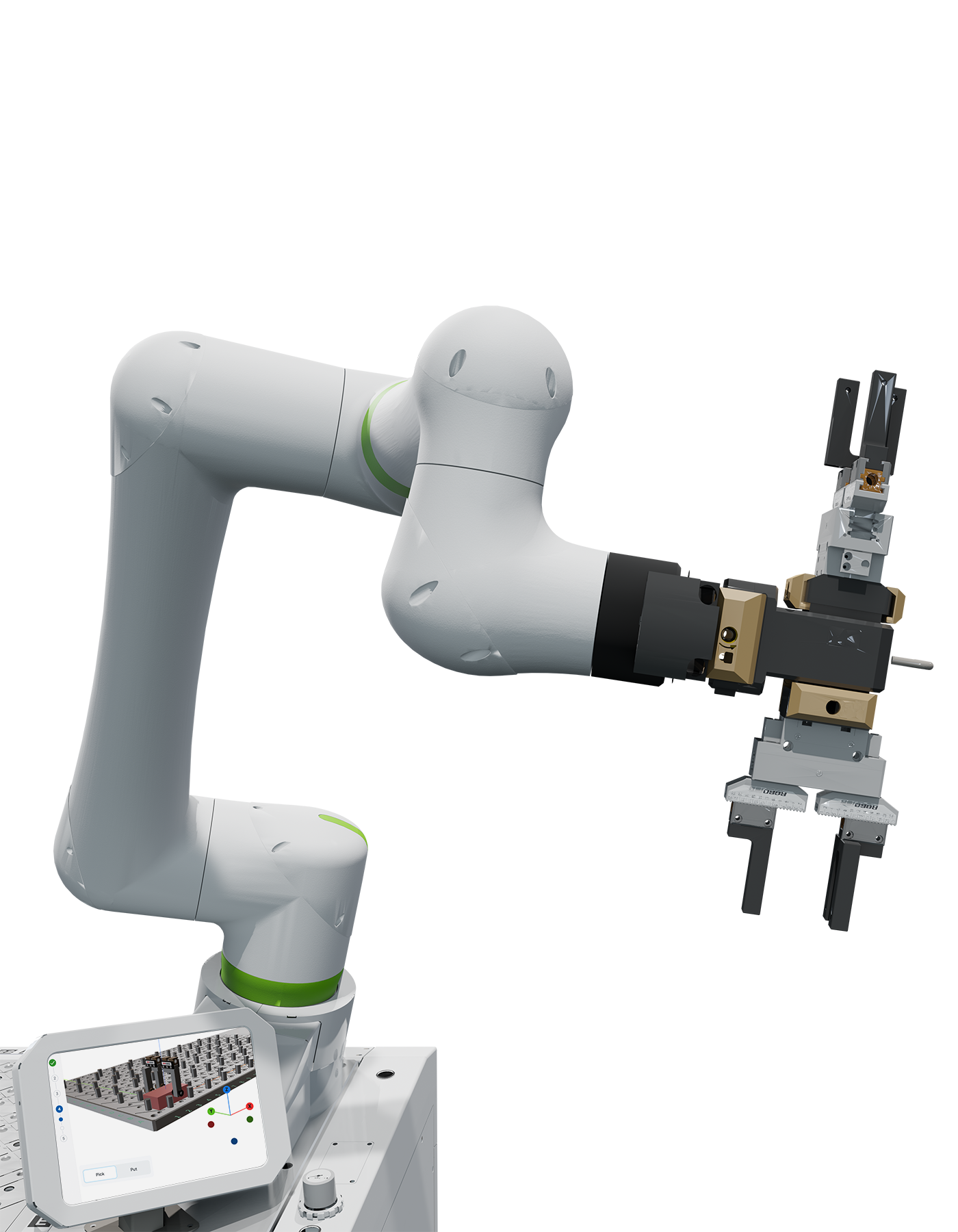

Flexible grip for any task

Thanks to its easy-to-change grippers, the robot will load your milling or turning machine in no time at all.

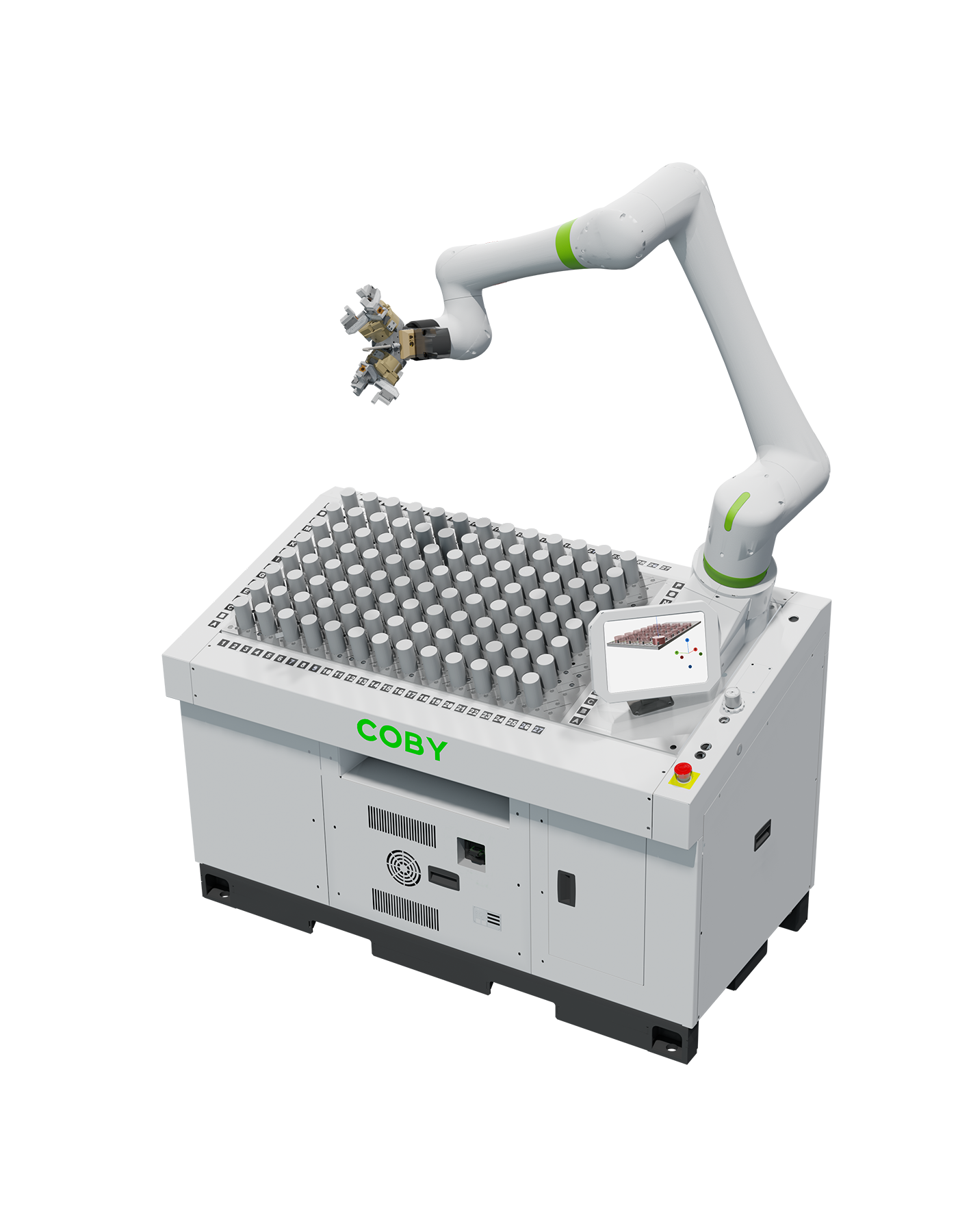

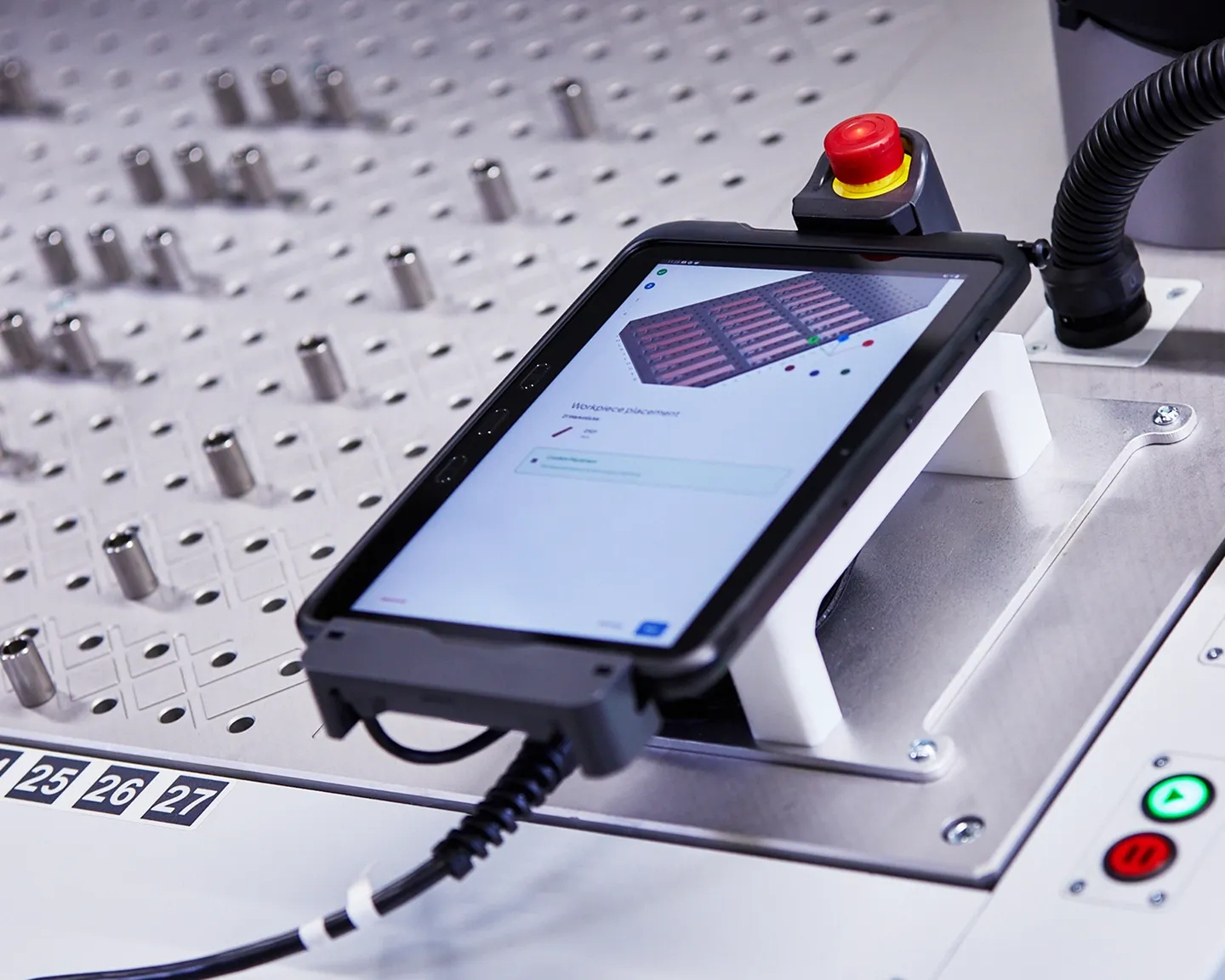

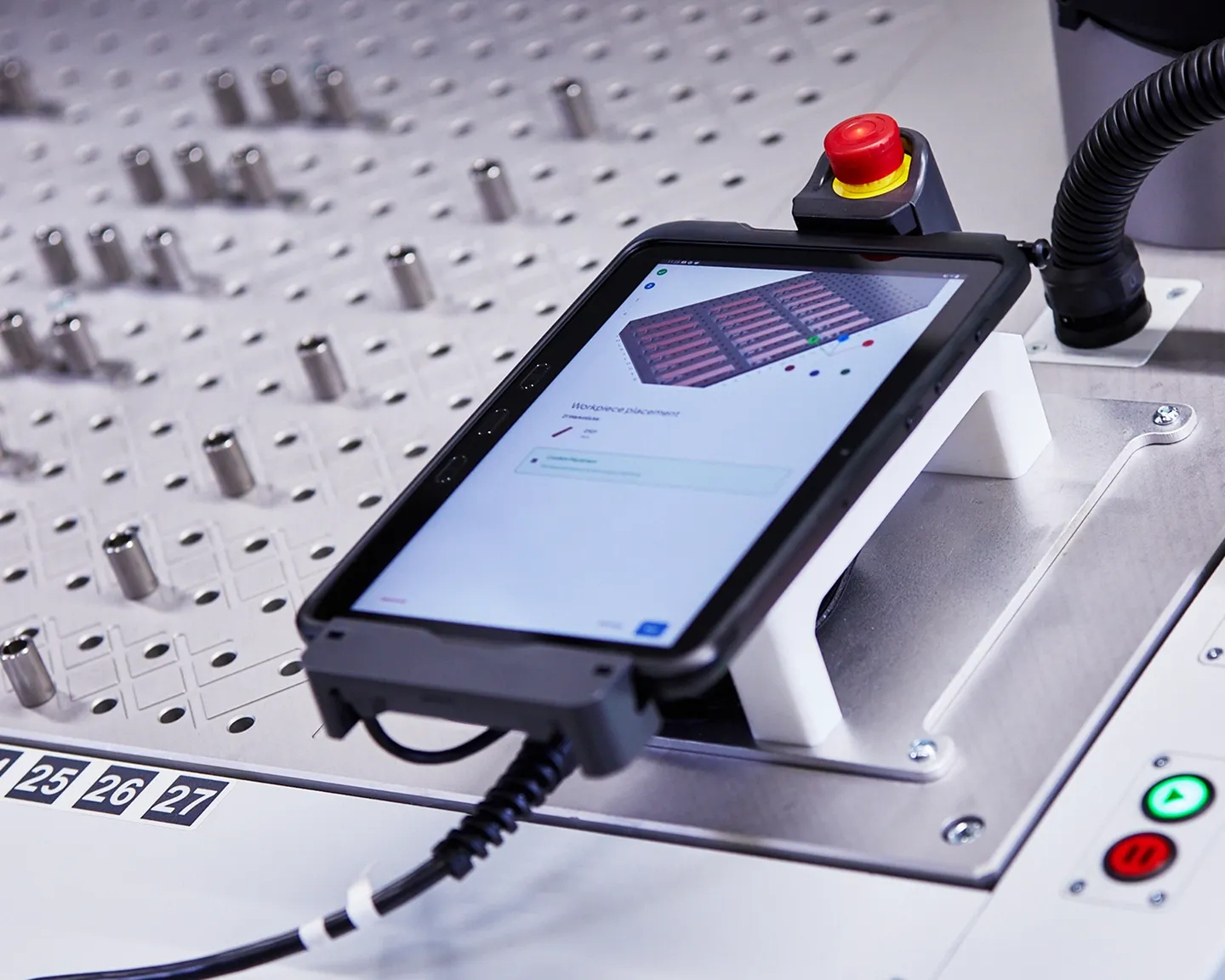

Easy setup on the stacker table

Once the workpiece is defined, the deposit pattern is generated automatically, and the operator immediately knows how to insert the pins in the grid system of the 80 cm high table. This makes setting up the robotic solution child's play.

Compact and flexible

Matching your requirements, we offer process-safe and extremely compact solutions for the automatic loading and unloading of your CNC machines.

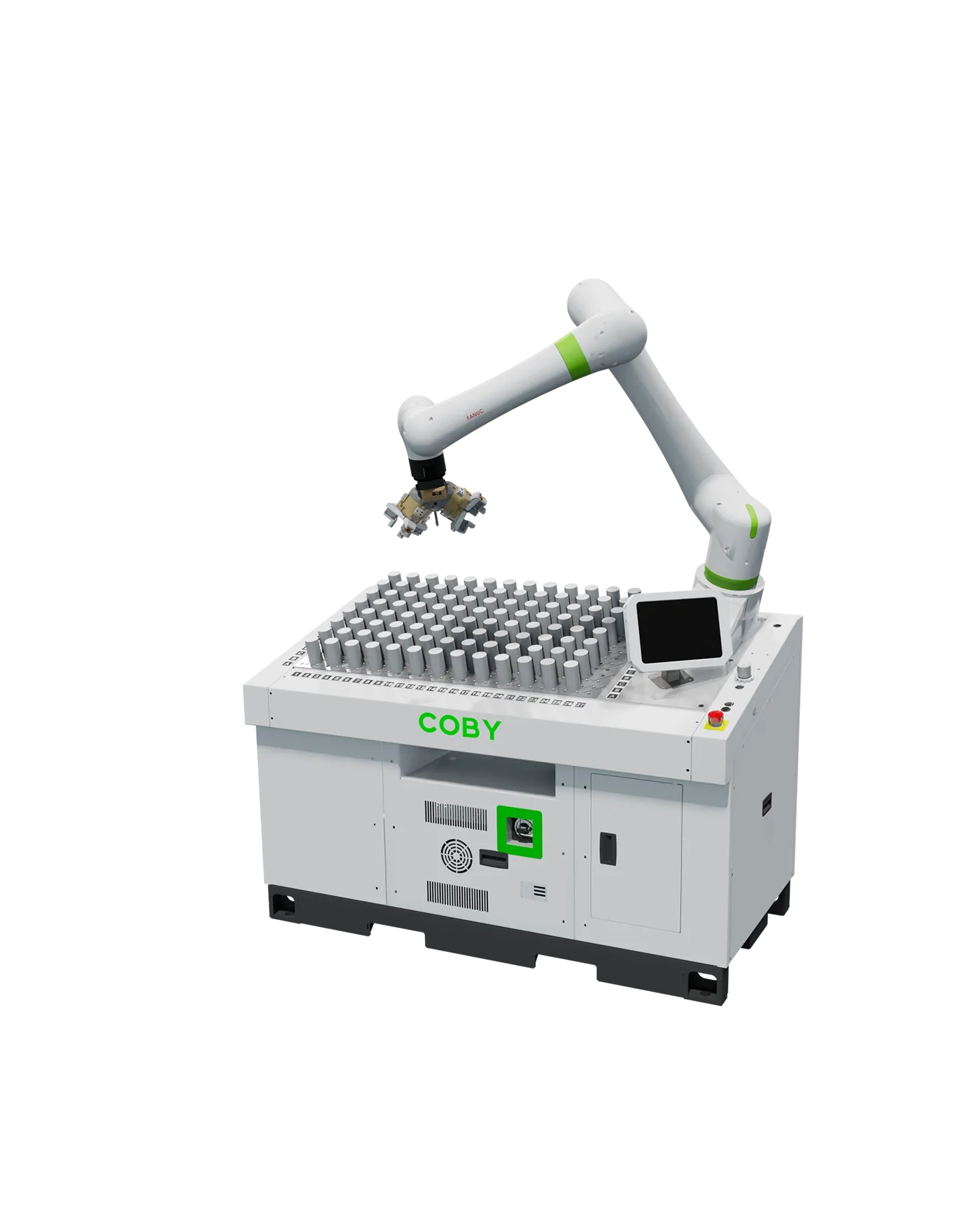

Intuitive software - programmed in minutes

Our solutions are equipped with a user-friendly software. This guarantees fast and uncomplicated setup. Even users with minimal technical knowledge can set up the system within minutes.

Turnkey solution, 100 % safety

We offer you a seamless integration, including CE certification. We adhere to all current standards and guidelines, ensuring you are always on the safe side. Our full-service-package includes:

- Documentation

- CE certification

- Training courses

- Service and maintenance

Robotic as a service

Flexible rental

With flexible rental starting from €2,080 / month, you can get started immediately without high upfront costs.

Non-binding trial period

Test our solution in your production for 4 weeks and convince yourself without risk – limited offer!

Fast delivery

Our robotic solution is delivered in just 6 weeks and up and running in one day.